|

Since

the early 1900's there have been tension rods with different

head sizes and lengths. Early banjo makers used similar tension

rods and keys for tuning banjos.

Exactly which came first, a banjo key or a drum key would

require more research and not part of this article. I did look

through many of the online patents in Google patents for drums

and banjos to see if there was a drum key pictured and I found

nothing. I did however notice that a key was mentioned as the

way to turn the tension rods on a variety of patents.

The

below patent from 1899 shows a tuning system that requires a

wrench to tighten the center nut that changes the tension on

both the top and bottom head equally.

1899

Drum Tuning Wrench

There

were other tuning systems that were attempted that were not

accepted by drummers. The Leedy Knob Tension Drums is one of

those systems which was a big marketing deal for Leedy as a

new way to tune drums without a drum key. It just did not work

and poor sales forced the new system out of the catalogs and

any future production.

Another

tuning method for drums which really dates back to the 1800's

and more recently popularized by Remo in the 70's is the spinning

of a drum to tune it. This method was used on early timpani.

There is no patent for the Roto Tom, but here is some history

on one of our other Drum Experts sites.

Another

product of the 70's was the Arbiter Autotune. This drum had

a special wrench to tune the heads. There were no tension rods

or lugs needed. The principle mentioned in the advertisement

is the heads would be screwed for tension like a jar with a

lid.

| Arbiter

Autotune Tuning System |

|

|

Here is

another system that looks very much like the Arbiter drums.

In

the 1980's Remo came up with the PTS - "Pre Tuned System"

of drum heads. The PTS system was a metal drum hoop with a pre-tensioned

drum head. To replace a drum head, the drummer had to just unclip

the hoop and put a new PTS head on. There was no tuning required!

Here

are some current tuning methods that do not require a drum key

to tune a drum. The Di Berardino Drums use a single cable that

tightens the entore head at one time.

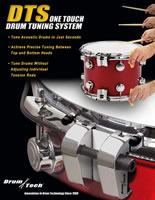

The

DTS one touch system works with any drum with standard lugs.

The system puts pressure between the lugs and the hoop, so all

you do is tighten one screw and the entire head tension adjusts

evenly.

Now

that we have information about some of the unique tuning systems

available, yes there are more not mentioned, I want to move

on to the most common way of tuning a drum. And that is the

good old drum key!

As

I was doing research on the topic, I began to realize that there

are no patents that I can find for a drum key as we know it

today. Besides the Gladstone Key, Ludwig Sta-Set and new keys,

I could not find any photo evidence, just a mention of a drum

key or tuning key in patents. This will remain a mystery to

me and something that will eventually be discovered or emailed

to me from a reader of this article. So, who invented the first

drum key? I'm still under the belief that it was either taken

from another instrument and used on a drum where it gradually

worked its way into the drum community and drum manufacturing.

This

is the shape we recognize as a drum key. This design has changed

since the early 1900's but the general principle has stayed

the same. A wing nut style top section with a built in socket

on the other end.

| Standard

Drum Keys |

|

|

There

have been some improvements to the functionality of the standard

drum key. Here are two keys that take the standard drum key

to a new level. The Spin Drum Key and the Drill Bit Drum Key.

| Spin

Drum Key |

Drill

Bit Drum Key |

|

|

Both

of these keys make the removal of a drum head quicker. Most

of the advancement in early "Technology" were all

under the premise of a quicker and easier way to take off a

drum head and tune a drum without using a drum key.

I

would say in the last 10 years, more unique advancements in

the design and functionality of the drum key have come to the

market. There are keys with lights, magnetic drum keys, flip

drum keys, clip drum keys, high tension drum keys and torque

drum keys.

This

is the Evans Drum Key with LED Light. There are times when you

have to change a head in the dark or poor lighting conditions

on stage, in a pit or club setting. So the LED would come in

handy. The other key is a key that folds up straight and is

more compact. Each of these keys has a detachable chain and

hook so they are easy to take off a key ring or a belt loop,

I can't tell you how many times I used a standard key on a set

of house keys and they just spin and hit the drum or jingle

when tuning a drum in a hurry.

| Evans

Drum Key with LED Light |

Evans

Key that flips shut |

|

|

These

two keys handle special functions. The Evans Magnetic Drum Key

is a strong magnet, so when you are taking a lug off the drum,

you do not need to hold it or grab it to take it off the hoop.

Just lift the key and the tension rod and washer go with it.

The other key is the Evans Wing Nut Key. These are meant to

replace the wing nuts on your cymbal stands so you always have

a drum key handy as long as you have your cymbal stands!

| Evans

Magnetic Drum Key |

Evans

Cymbal Wing Nut Key |

|

|

Here

are two keys that make the drum key a handy device not to be

left in a pocket or clipped to a stick bag. The Tweek key clips

on to any 1" tube from a cymbal stand, hi hat or snare

stand and the Ahead Klip-It key clips to a drum lug and is designed

not touch the shell or allow any metal to rub or hit together.

| Tweek

Clip Drum Key |

Ahead

Klip-It Drum Key |

|

|

These

two keys have special gearing inside the key. The Firefly Key

lets you tighten the key without winding your wrist or having

to turn the key, then lift your hand and turn the key. It has

a built in ratchet, very similar to a ratchet for a socket set

that lets you tighten, then pull the ratchet back without any

tension or sound. The Robo Key has an advanced system that multiplies

the turning of the key with special internal gears.

| FireFly

Ratchet Drum Key |

Robo

Key Ratchet Drum Key |

|

|

These

two keys both work like a mechanics torque wrench. When a bolt

on a motor needs to be tightened to a specific torque you set

the wrench and then when it reaches the desired tension it clicks.

These two keys work on that exact principle and once you set

the key to the tension you like, you just turn it until it clicks

on each lug.

| Rhythm

Tech Torque Key |

Evans

Torque Key |

|

|

Tuning

for marching and pipe drums require an excessive amount of high

tension. These two keys provide the extra power to tighten them.

| Cannon

High Torque Ratchet |

GrooveTech

High Torque Wrench |

|

|

Even

though there have been some very unique tuning systems since

the time of early drumming the main tuning system has been the

drum key. The main reason is the ability to use different hoops,

the cost of making them and the history of the drum. The other

unique systems are dependent on the drum and also more expensive

to manufacture.

In

the end, learning how to tune a drum using a drum key takes

practice and patience, but once you get your system down, it

becomes second nature to many drummers.

Vintage

Drum Guide

|