| I pondered on this topic for quite some time as to

whether it would be useful to people in and outside the vintage

drum community. Some of it is my own personal technique and other

information I found on drum forums. I offer this information for

the person that has never done this before or for the seasoned

drum cleaner to maybe pick up some new tips. Also, many restorers

use proprietary methods that they normally do not share, so there

are many more methods and techniques not in this article that

work just as good! Hopefully it will save another drum from steel

wool! |

Always start by taking pictures of the project so you can document

the change when it is done!

Step 1: Find the project snare

drum

a. Metal Shell (COS, COB, Copper, Nickel, Aluminum Etc..)

b. Wood Shell Stained

c. Wood Shell Wrapped

d. Wood Shell Painted

e. Vistalite Shells (Acrylic)

Step 2: Disassemble the drum

Supplies:

Plastic bags or plastic containers with lids

Sharpie marker to label the bags or containers

Phillips and Regular screw drivers (I prefer different sizes)

Small socket set (do not use Vice Grips, Crescent

Wrenches, Robo-Grips or anything that can hurt the nut when it is

removed)

|

|

|

|

a. Take a photo if you can. Either digital or film to document

the drum and the project in case you need to reference the picture

later to see how something was mounted.

b. Remove the tension rods from the top and bottom heads and put

them in a plastic bag and label them

c. Remove the lug casing screws and and put them in a bag and

label them.

d. Personally I like to work on a piece of carpet scrap on a work

bench so I line up the lug casings with all of the internal parts.

spring, internal felt, lug screw inserts etc... Normally I do

not bag the lug casings so they do not scratch against each other.

e. Remove the tone control and bag it as well as the strainer

and butt. That is a good time to take notes on how the washers

are in reference to the inside and outside of the snare. |

Step 3: Begin Cleaning the parts based

on condition

Supplies: Standard Cleaning

Soft cloths

Cotton Balls

Q-tips

Metal Polish (Flitz, Groove

Juice, Brasso, Brite Stuff Cymbal and Drum Polish or your favorite

metal polish) -- Used to polish all of the

metal parts

Masking Tape -- Used to tape the inside of

any holes on a shell to protect the wood

Fine Steel Wool (DO NOT USE ON CHROME

PARTS) -- Great for tension

rods and tension rod inserts

Lubricant (Petroleum Jelly, Clear Lubricant, etc..) -- Lubricate

the tension rods, strainer and all of the screws

Supplies: Pitting, Rust, Grunge

Same as above

Wink --

Removes Rust

Bon-Ami

+ Dawn

Dishwashing Soap -- Removes grunge,

dirt, rust, or grease. Just get a bowl or plastic container and

mix a little of both and put the parts in. You can add just a

little water to make it thinner, then with the tooth brush or

sponge clean the parts.

WD40 -- Removes Rust and cleans parts.

Not a lubricant like a silocone spray.

Plastic or glass bowls containers -- These

are for holding parts when they are being cleaned

Scouring Pads, Sponge or Toothbrush -- Great

for the dirty work and getting into the grooves on screws |

| You may not use all of the products above, but they are examples

of items that work. Please do not experiment by mixing cleaners

since this may cause adverse reactions. No need to pass out while

cleaning a drum! |

Standard Cleaning:

Here is a picture of the parts*

listed below.

Click on the image for a larger version. |

|

*Other people may

use different names for these parts

Lug Casings:

I start with the lugs. I take one lug and remove the interior

parts and place them on the work surface. I take a Q-Tip dip it

in the metal polish and work it all over the lug and set it down

and repeat the step on 3 or 4 lugs. I have a first buff and second

buff cotton towel. I give the part the first buff which takes

off the majority of metal polish then I follow up with the cleaner

towel and give it a final rub taking my time and making sure it

is all shiny. During this process I never touch the part with

my hands. It is always handled in the towel. I place it back in

line with the internal parts. |

Internal Felt:

I usually leave it alone, if the lug does not have internal felt

then you can pack it with a cotton ball (if that's all you have)

or go get some heavy felt at the fabric store. Cut it in little

rectangles so that it wraps around the spring |

Tension Rods:

Tension rods can be in a variety of conditions so it really depends

on how bad they are. If it is a basic cleaning then a good soak

in the dish soap and cleaning with a tooth brush will do the trick.

I then follow up with a little metal polish. If they are rusted

then you can use a more advanced method of cleaning which is used

by a variety of professionals. I also gave a modified version

if you do not have the equipment. For this you will need a bench

vise, a drill with a drum key bit on the end and some steel wool.

Take the drum key and wrap it with the steel wool then clamp it

in the vise so it is snug, but not too tight. Then take the drill

and run it in forward and reverse a few times or until the rust

is off the tension rod. I also add a little metal polish to the

lug before I begin. If you do not have all of that then the same

thing can be done a little more labor intensive with a pair of

vise grips, steel wool and a regular drum key. Just put the tension

rod in the steel wool (with a little metal polish on it) and clamp

it gently into the vise grips then turn the key in and out until

the rust is gone. This method takes longer but is quiter and requires

less equipment. |

Spring:

Since this is a standard cleaning the spring should already be

pretty good and I personally just leave it alone. |

Lug Insert:

A lot of times these have improper lubricant and it is black or

brown or just covered in grease so I take the steel wool and pull

it apart and make it pencil like and fit it in the lug insert

and screw it into the steel wool. this really cleans out the threads.

If the exterior of the lug insert is dirty I use the metal polish

and clean it up. |

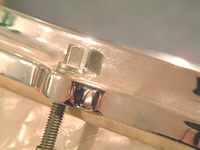

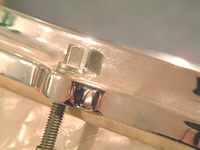

|

Rims:

Since these are in decent shape on a standard cleaning then I

just go ahead and apply the metal polish to the inside and outside

of the rim. With a towel in each hand I work the rim around a

few times. I then follow up with another towel to really give

them a good shine. I use Flitz for all of my chrome work. The

only cleaner I do not use is Brasso, but if you have it in the

house then give it a test and see how it works. |

|

Strainer and Butt assembly:

If the strainer can be taken apart then I do. This way I can clean

the slide section that the strainer requires to move up and down.

I also polish this and then apply a small amount of lubricant

to keep it moving smooth and worry free. |

|

Badge:

This is a standard Ludwig Keystone Badge and personally when I

work on a badge I take extra time in cleaning it. In some cases

they are painted. I would use wax instead of metal polish to clean

it. If the badge is totally destroyed or bent then I would likely

find a replacement if I wanted the drum to be as perfect as possible.

I have seen other discussions on this topic and if you really

have to remove it then you can visit my section on "How

to Re-Wrap a Drum" and learn 4 types of badge removal

techniques. |

|

|

For a complete image

of all of these components on a 1970's Slingerland Snare drum

click the graphic on the left |

|

Shell: Metal

If it is a metal shell I will also polish it with the metal

cleaner. Normally if the interior is fine then I just leave

it alone. In many cases the interior has an ink stamp, paper

tag or other identification mark, so you have to be careful

not to damage these very important identification marks.

|

|

|

Shell:

Stain

If the shell has exterior stain then I will use Scott's

Polish to give it a nice shine and protect the wood. If the

interior is natural I will also use it on the inside of the

shell as long as I do not affect any ink stamps or identification

marks from the manufacturer. It is important also that you spray

it on the rag and not all over the shell. You could use any

household polish or professional grade protector you choose,

but just be sure it is not oily and dries without leaving a

residue on the drum. |

|

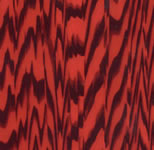

Onyx or Agate Finish |

Satin or Satin Flame |

Sparkle |

Pearl Finish |

|

|

|

|

Shell

Wrap:

If the wrap is in good shape then I would probably get a high

quality car wax, guitar

polish or similar product and give the shell a nice protective

coating.

In some cases if you have the experience level the shell can

be wet sanded with 1500 to 2000 grit sandpaper. This would require

that the interior holes be taped with masking tape and you take

a great deal of time to get it even and you don't sand to much

into the finish. Then a clear coat (Krylon

Products) can be sprayed on to give it a really nice shine

and bring the wrap color back. I have never tried this technique,

but will be very shortly on a wrap that has scratches and hazing

on the shell from the previous owner. I was also told to use

the Gloss Clear Coat.

*I would not try this method with a rare

finish or a satin flame* |

Special note for WMP (White Marine Pearl)

Many people ask if they can bring back the original WMP color

of their drums. I would say NO. You will never get back to the

original color, but there is a technique used by experienced drum

restorers that will take off some of the yellow and get them close

to the original and looking much better then it originally did. |

Shell Painted:

If the shell has no scratches then I will wax it with any high

grade car polish or guitar polish. On the other hand if the shell

has small scratches or surface scratches then a high quality non-abrasive

buffing compound can be used before you polish. I usually test

it under a lug to see how it is going to work. In some cases I

do the buffing twice and the waxing twice to really get it shining

nice. |

|

|

Shell: Vistalite

(This is after the hardware is

removed)

With the bare shell you you can take a mild dish soap and a

soft sponge or cotton towel and clean the shell. Remove everything,

because any small particulates can scratch the shell in the

buffing and waxing process.

Novus 1. General cleaning and buffing

Novus 2. Light Scuffing

Novus 3. Heavy Scuffing (Follow up with Novus 2)

Scratches will require a completely different method and will

not be discussed in detail. It will require wet sanding and

very fine sandpaper.

|

|

Rust:

|

Here

is a group of rusted parts from a 50's Gretsch Snare Drum. It

is not uncommon to find a drum that is completely free of rust

except the internal parts. This is the second drum I found like

this. The picture on the right are the same parts after the

Whink treatment. |

|

Rust is another big topic among drum restorers and requires

some special attention. Once rust is on an object more then

likely the metal underneath has been eaten away. So if you remove

the rust you will probably have bare metal. In a lot of cases

the item may have surface rust, which means it has not officially

attacked the metal underneath and can be removed without hurting

the part. Steel wool was the common method, but in many cases,

depending on the quality of the chrome will hurt it and create

little scratches in the metal. I recently started using a product

called Whink rust remover.

This is in a little brown bottle and can be purchased at most

grocery stores or large superstores like Wal Mart. The product

requires special attention protecting your hands and making

sure it is used correctly. The parts I used it on were clearly

rusted and after sitting in the Wink the rust was gone. It was

surface rust and the metal underneath was pretty much intact.

(Only to be used on screws and

other non-chrome parts)

Using metal polish will also remove surface rust and requires

a certain level of elbow grease and special attention to remove

it. Like anything, if you take your time it should come out

just great.

If the rust has really taken hold then more aggressive methods

are required and this in turn will take all of the exterior

metal off as well. At that point it will need new metal and

will have to professionally be prepared for a new metal surface

to be added. The metal shop will probably dip it in acid and

that will remove everything and get it ready for re-plating

of the metal of choice.

This is expensive, so make sure you know what the cost is up

front. I have heard of collectors plating in Gold on snares

that were originally Gold to bring them back to original condition. |